Blog : Modular Aqua feed installations

Organization of the United Nations reports that the majority of aquaculture production small comes from developing regions in the world. Building an aqua feed mill in these regions could be challenging as mechanical and electrical installation services are not always easily available. Containerized or partially containerized feed mills could offer a perfect solution for this challenge.

Modern-day feed mills could be designed and built as either a conventional or containerized feed mill. A conventional feed mill design requires the main building or superstructure to accommodate and support all the equipment required by the process.This design approach suits very large feed mills well. Containerized feed plants, on the other hand, are designed in a modular way, and normally contain all the plant equipment, electrical installation and process control equipment, assembled and installed into support structures the size of one or multiple standard 20‐foot shipping containers.

These modules or containers are laid out in a main building or superstructure that becomes a “shell” protecting the plant from the elements without the direct support of the equipment.

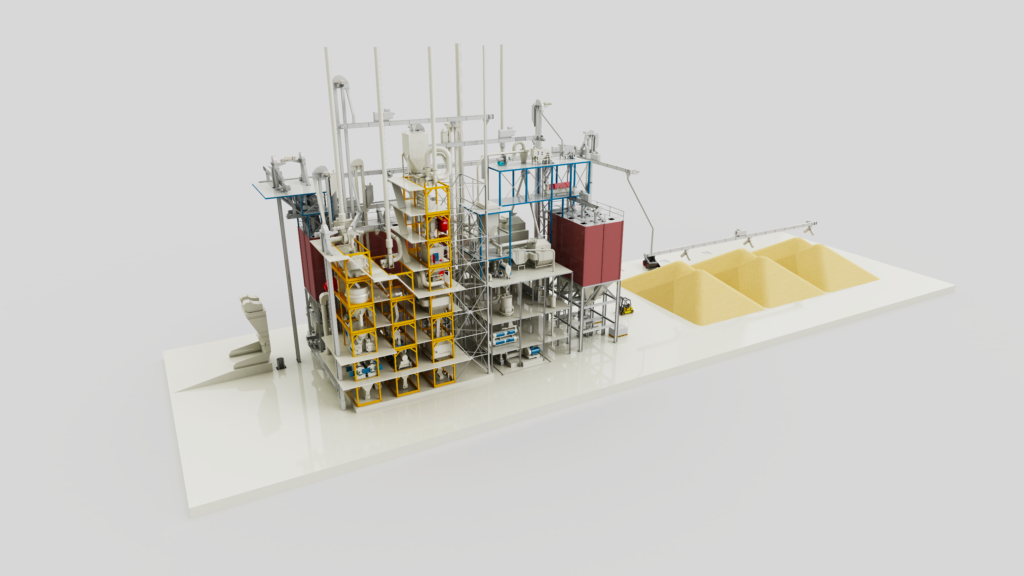

Containerized and partially containerized feed plants as shown in Fig. 1, suits the requirements and scale of Fish Feed manufacturing in especially developing and remote areas very well.

There are many advantages opting for a containerized or partially containerized aquatic feed plant. The following white paper show the most obvious advantages and characterizes of containerized plants.

Whitepaper Modular Aqua feed installations

Click here to download our whitepaper about modular Aquafeed Installations

If you have any further questions, we will be happy to assist you.

You can send an e-mail to mkp@ottevanger.com.

Read more: