Special execution

- Automatic feeder (optionally frequency controlled)

- ATEX 22 certified components

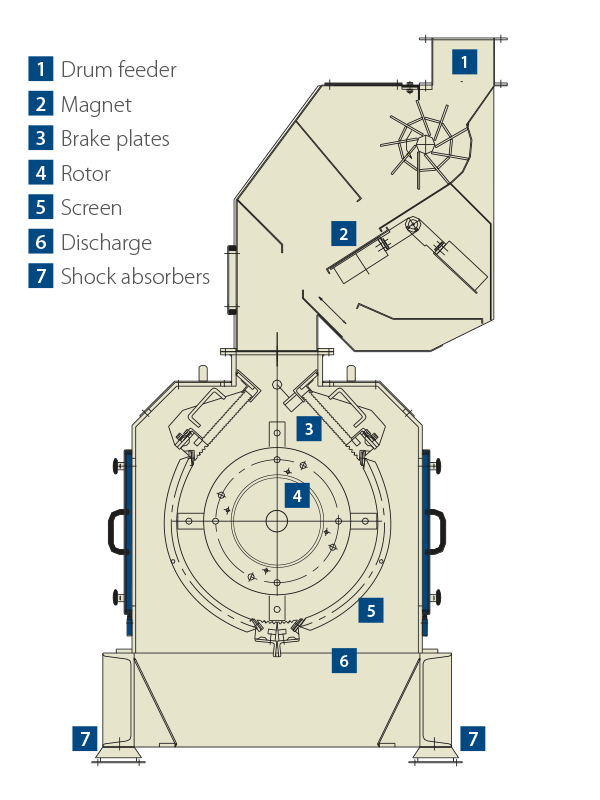

Feeding System For optimum efficiency in grinding it is essential for the feed to be even and for the ground product to be discharged as fast as possible from the grinding chamber. The mechanically driven feeder ensures an even feed over the whole width of the mill and the automatic load control controls the feed in proportion tot he load on the main motor. The drum type will provide a full load in 10 seconds from start up. It includes a permanent magnet and stone trap, and an auto magnet cleaning device.