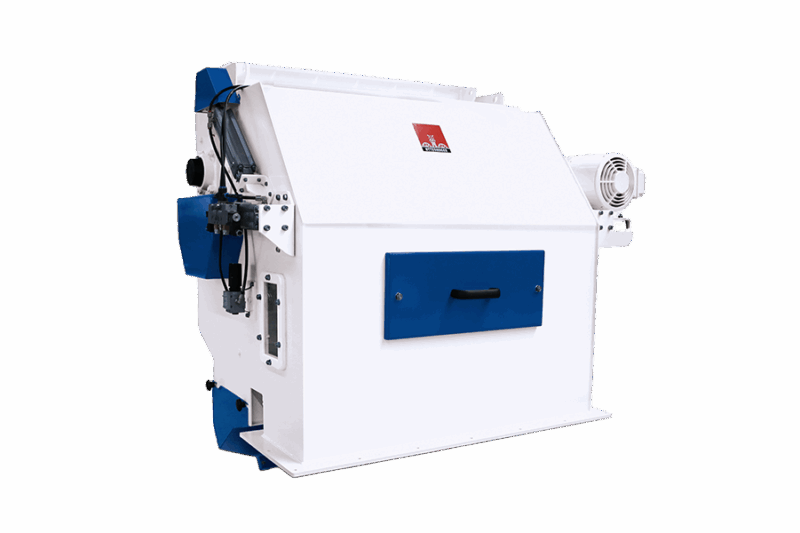

Protector Roll Feeder

- Even, uniform feed distribution

- Integrated drum magnet

- Self-cleaning screen

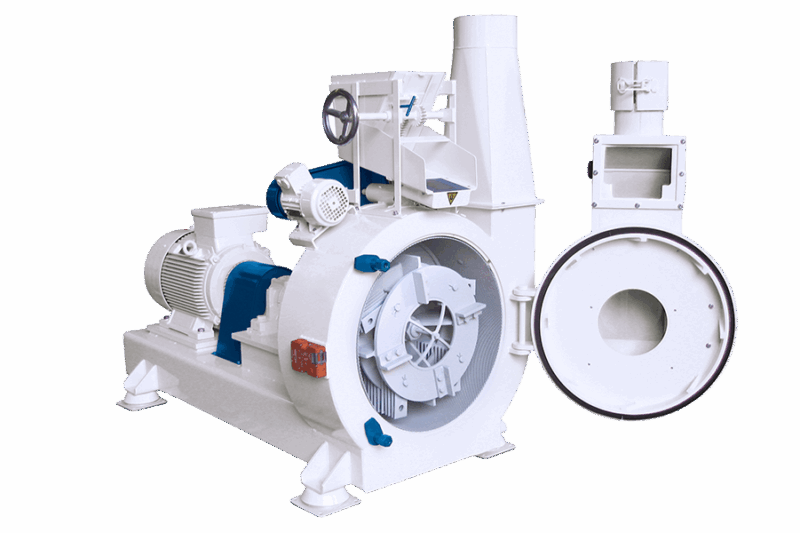

Grinding and structuring are the starting point of every feed plant. Proper particle-size reduction boosts feed efficiency by increasing grain surface area, improving nutrient uptake and animal performance. It also strengthens pellets, raises pellet-mill capacity, and reduces die and roller wear. Modern roller mills cut energy use and noise while delivering a more uniform grind. The result is cleaner, more stable feed with better flow, less dust, and reduced fire and explosion risk.

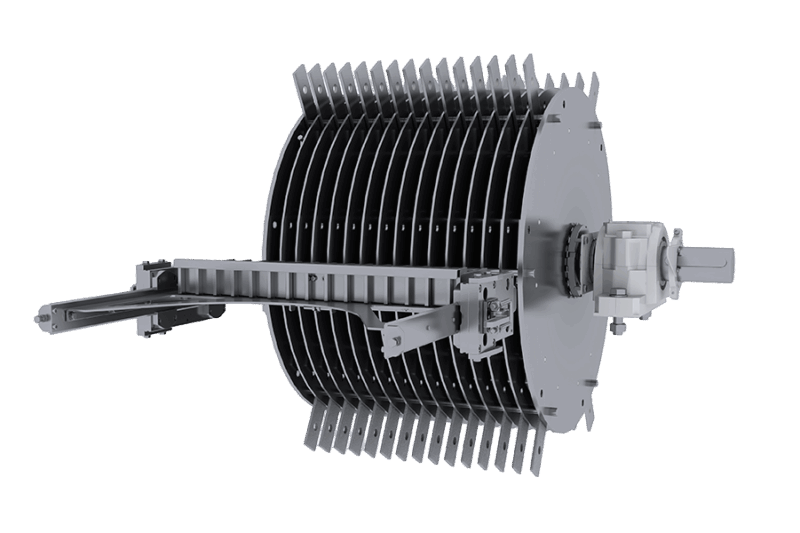

For the grinding phase of feed production, it’s a given that operators need trusted equipment that creates a consistently and evenly ground product. But it’s also essential to release that product as quickly as possible for its onward journey. Our hammer mills and grinding equipment deliver all this and more. Created through a century of the finest Dutch craftsmanship, they can handle granulates of up to 20 mm diameter and can reduce the particle size down to 200 microns approximately. Just as importantly, the other key quality they all share is extremely high efficiency.