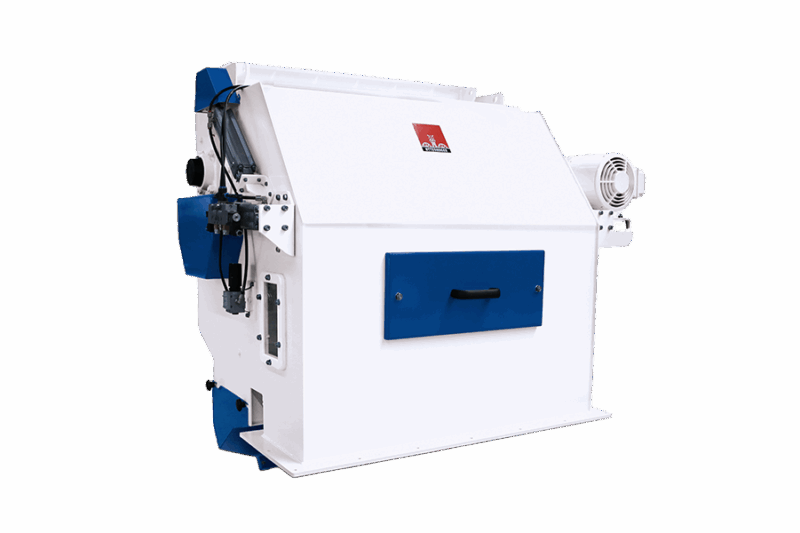

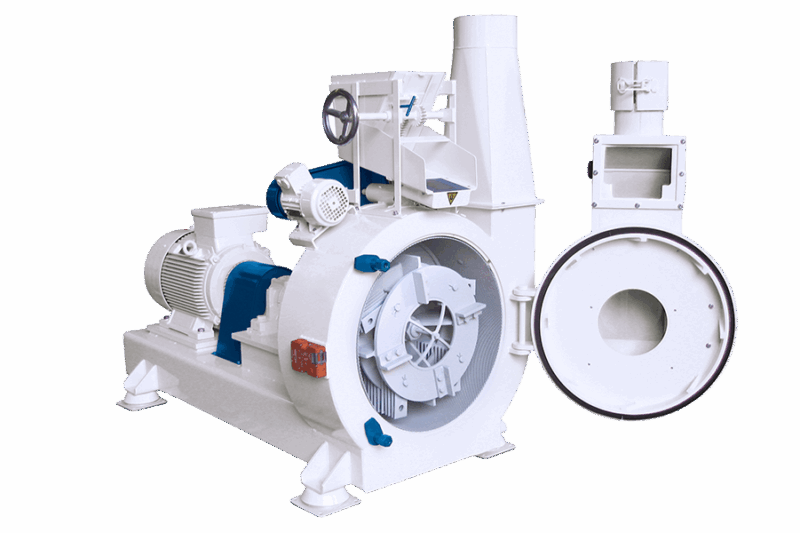

Roller Mill

- Dual-rotation feeder with bypass

- Precise gap control to 0.01 mm

- Riffled rollers with differential speeds

The Ottevanger Protector Roll Feeder is installed before a roller mill to pre clean and distribute product evenly. It screens out coarse debris and removes ferrous particles with a drum magnet, using self cleaning screen strips for reliable separation. Contaminants are discharged by a shaftless screw, with a by pass valve for oversize recirculation and large hatches for quick inspection and cleaning.

Performance & Applications

Discover the key benefits of the Protector Roll Feeder, designed to protect the roller mill and stabilise upstream product flow.

All machines can be customised. The Protector Roll Feeder can be configured to match product characteristics, capacity and mill width.

Every successful project starts with a conversation.

No matter what your needs, we have all the equipment and process expertise to help you achieve it. Contact us today and let’s talk.