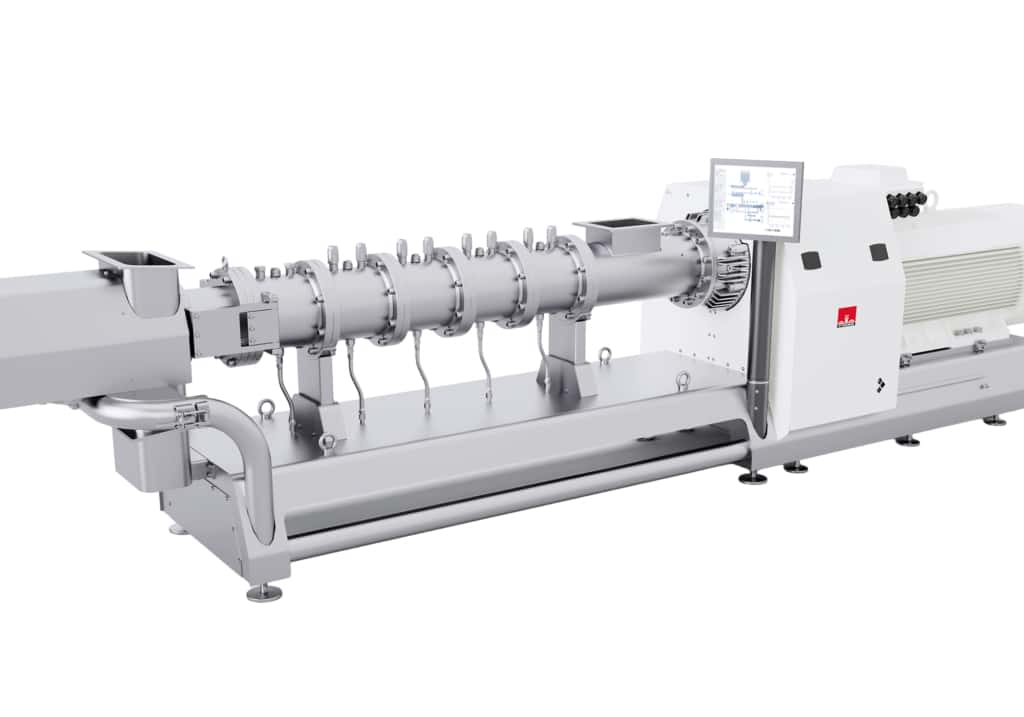

Extruder AL-series

- Proven single-screw extrusion technology

- Compact and durable construction

- Consistent product quality

The Ottevanger Extruder AXT Series is built for high performance extrusion of pet food, aquafeed, and specialised diets. Starch and protein ingredients are cooked, expanded, and shaped under controlled conditions for consistent results. A durable design with precise control, direct drive, cooling sections, and fine knife adjustment ensures efficient, long life operation in demanding applications.

Extrusion is used to maximise the nutritional value of raw materials, reduce anti-nutritional factors and achieve a consistent, high-quality end product within strict product specifications. Almex extruders are suitable for pet food, aqua feed, animal feed and grain processing, as well as recipe densification and pre-conditioning. Their design focuses on technical reliability, simplicity and easy access, supporting stable, efficient production over the long term.

Performance & Applications

Discover the key benefits of the Extruder AXT-Series, designed for precise, efficient, and high-capacity feed production.

All extruders can be tailored to specific product and process requirements. The AXT-Series is available in multiple power configurations and can be equipped with various control and discharge systems.

Every successful project starts with a conversation.

No matter what your needs, we have all the equipment and process expertise to help you achieve it. Contact us today and let’s talk.