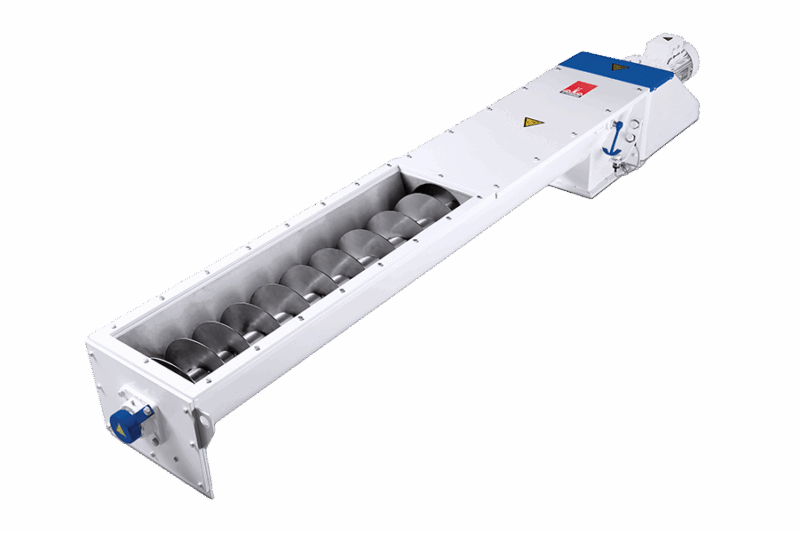

Feeder Screw

- Uniform, consistent product flow

- Durable stainless-steel construction

- Low maintenance, long service life

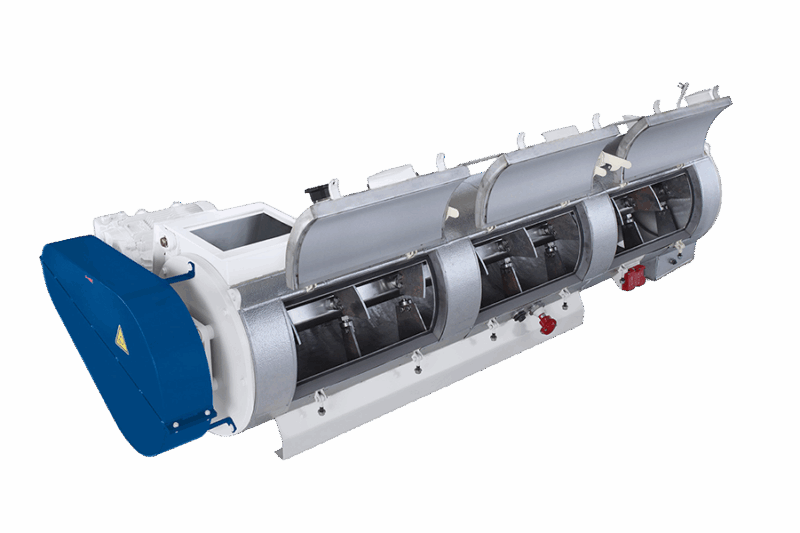

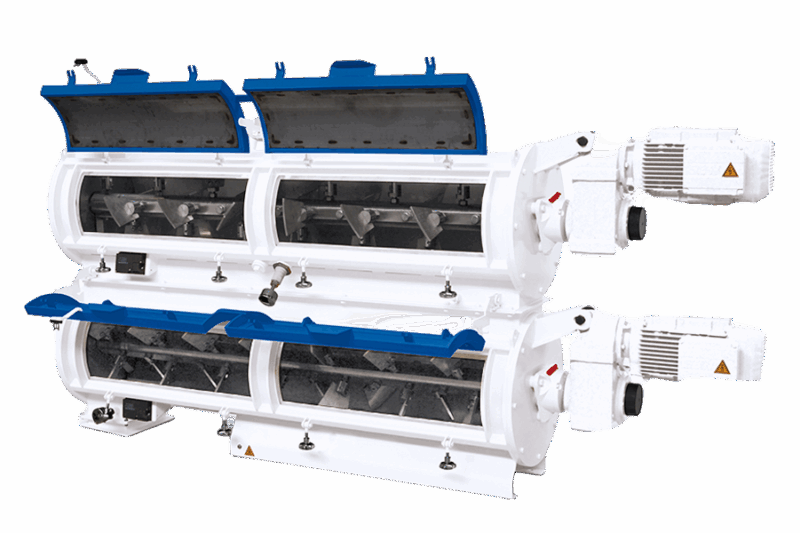

The Hot Start Conditioner is a closed, heated mixing chamber for consistent thermal treatment of meal and powders. Steam and liquids are added through the shaft, with large adjustable paddles ensuring uniform mixing. Electric heating and PT100 sensors control discharge at the set temperature, delivering full conditioning from start up for improved feed safety, higher efficiency, and reliable bacterial reduction.

The Hot Start Conditioner provides a thermally stable process from the first batch by combining insulated housing, controlled electric heating and precise steam dosing. Bidirectional shaft rotation and adjustable paddles ensure uniform mixing and consistent heat transfer. Accurate temperature control prevents fluctuations at start-up, improves process repeatability and reduces mechanical and thermal stress on downstream equipment.

Performance & Applications

Discover the key benefits of the Hot Start Conditioner (TCS)

Sizes and capacities:

Every successful project starts with a conversation.

No matter what your needs, we have all the equipment and process expertise to help you achieve it. Contact us today and let’s talk.