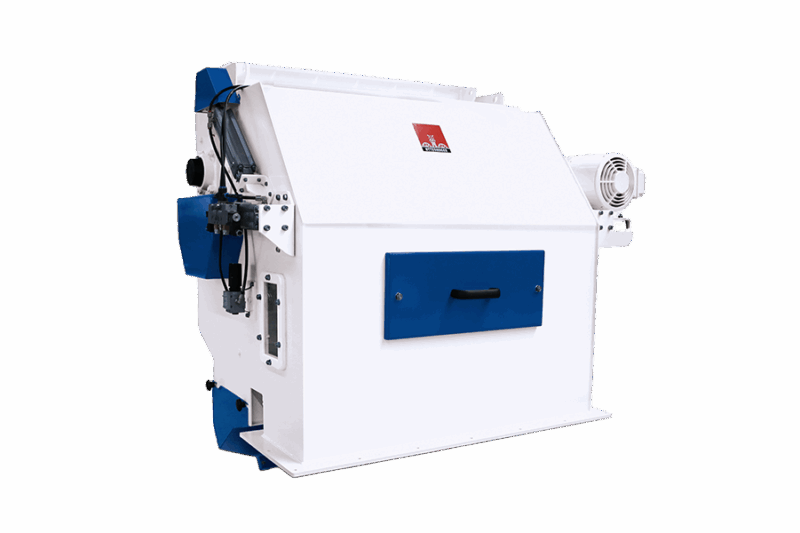

Protecteur pour broyeur à cylindres

- Even, uniform feed distribution

- Integrated drum magnet

- Self-cleaning screen

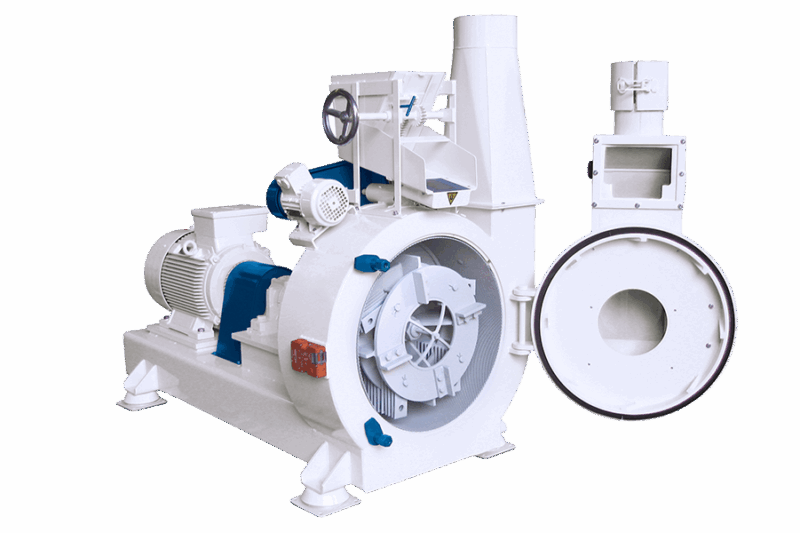

The Ottevanger Roller Mill crushes or structurises grains, oilseeds, and biomass efficiently with low energy use. An integrated rotating feeder spreads product evenly and allows bypass. Large riffled breaking rollers and downstream structurising rollers produce uniform particles with minimal fines, with easy access for cleaning and maintenance.

The Roller Mill is designed for breaking and structurising grains, oilseeds and biomass with high accuracy and low energy consumption. An integrated dual-rotation feeder ensures even product flow or bypass, while large-diameter rollers deliver consistent particle size with minimal fines. The modular design allows capacity expansion, improves access for cleaning and maintenance, and supports stable, efficient operation.

Performance & Applications

Discover the key benefits of the Roller Mill HE, designed for uniform particle size reduction with reliable operation and low maintenance.

All machines can be customised. The Roller Mill HE can be configured to match the required capacity, product and plant layout.

Elk succesvol project begint met een gesprek.

Wat je ook nodig hebt, wij hebben de machines en proceskennis om je verder te helpen. Neem contact met ons op en we denken met je mee.