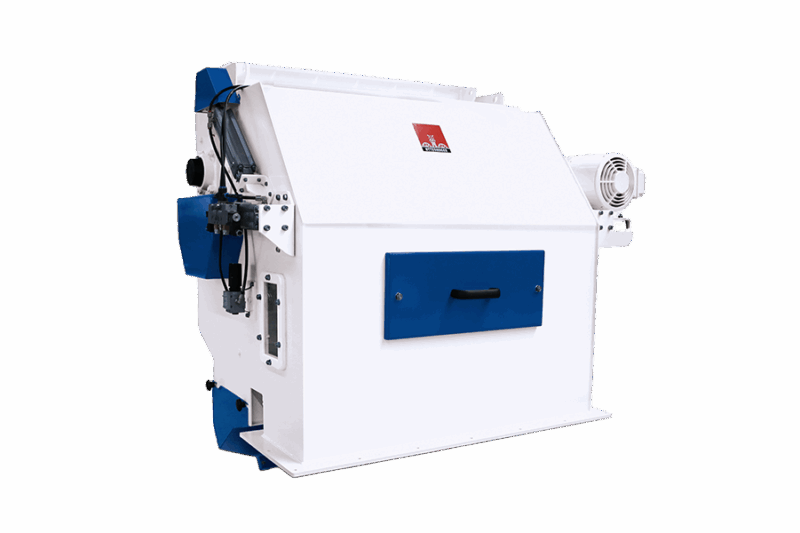

Protector Roll Feeder

- Even, uniform feed distribution

- Integrated drum magnet

- Self-cleaning screen

The Ottevanger Hammer Mill 670 delivers efficient, consistent grinding for feed production, down to about 200 microns depending on rotor speed and screen. It features dual rotation, a product guide valve, breaker plates, and rupture discs. An optional rotary feeder evens out feed and the product exits the chamber immediately for high efficiency.

Performance & Applications

Discover the key benefits of the Hammer Mill 670, designed for efficient, reliable grinding with minimal downtime.

All machines can be customised. The Hammer Mill 670 can be supplied with options and sizes to match required capacity and product.

Every successful project starts with a conversation.

No matter what your needs, we have all the equipment and process expertise to help you achieve it. Contact us today and let’s talk.